As standard your XL800 comes with:

- Six high-speed inputs and one relay output for core signals

- A sixteen input expansion card and six-relay output card

Inputs can trigger internal counters, process timers or programs. Programs also let inputs act as “soft buttons” that change the operation of the display based on conditions which are defined by you, such as a break on-the-fly button.

Relay outputs are not designed or intended for control applications – they are for annunciation only.

Three concurrent communication ports provide multiple options for reading and writing data to the XL800 lean manufacturing tool:

- 10/100 Ethernet (for the ultimate in data acquisition)

• RS-232 (single point connections to 57,600 bps)

• RS-485 (multiple point connections to 115,200 bps)

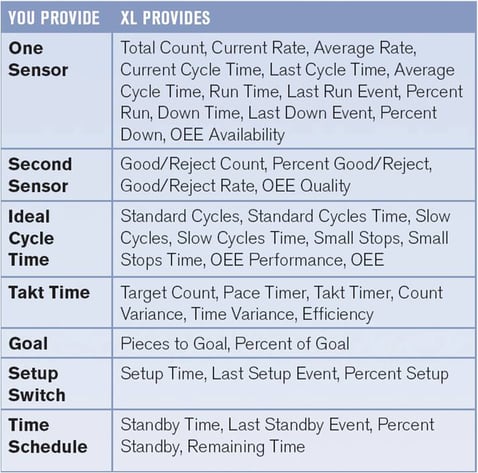

The XL800 works as a true bolt-on system and only needs 2 signal inputs from your line to immediately start providing you with over 50 core KPI’s straight out of the box: