For any business that involves manufacturing, maximizing efficiency is critical in improving the business’s profitability and growth.

Manufacturing efficiency is achieved when the company successfully produces products with the lowest possible total costs and at the fastest possible time, and obviously, achieving it can be easier said than done.

In this article, we will learn all you need to know about how to improve manufacturing efficiency to maximise your business’s output while minimising your resource usage and losses.

Without further ado, let us begin.

OEE for measuring manufacturing efficiency

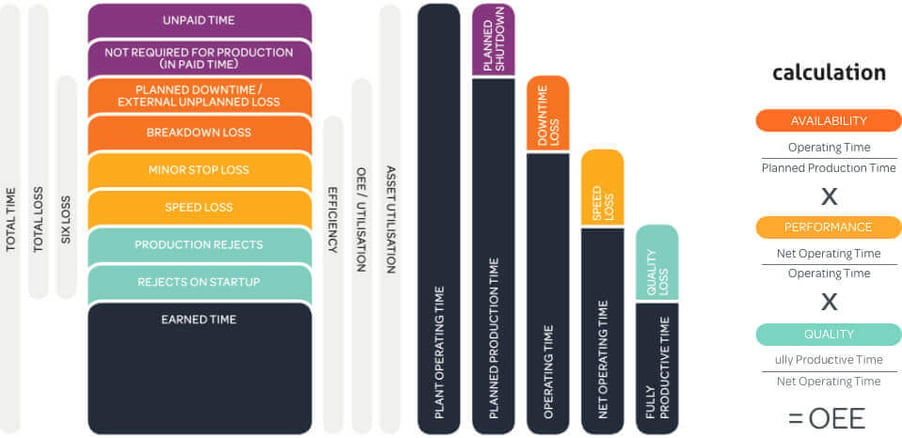

OEE stands for Overall Equipment Effectiveness, and as the name suggests, it is a metric used by equipment-intensive organizations (i.e., manufacturing companies) to measure an equipment’s effectiveness in its operation across different aspects (hence “overall.”)

OEE is widely regarded as the gold standard for measuring productivity in manufacturing all around the world.

In a nutshell, OEE measures the percentage of operation/manufacturing time that is truly productive and successfully produces non-defective products. OEE is measured by taking into account three main elements: quality, performance, and availability.

- Availability. Measuring planned (i.e., maintenance) and unplanned (i.e., failure) stops during a Planned Production Time. An availability score of 100% means that the equipment is 100% running during Production Time without any Planned or Unplanned Stops.

- Performance. Measuring Slow Cycles (when the equipment is running slower than usual) and Small Stops (when the equipment stopped operating for less than 10 minutes.) A Performance score of 100% means the equipment is running as fast as possible without small stops during Planned Production Time.

- Quality. Representing the percentage of good products/parts manufactured in the process compared to total parts/products produced. A Quality score of 100% means there are no defective products manufactured during the measured period.

OEE and Six Big Losses

In relation to OEE, the Six Big Losses offers a perspective on how a piece of equipment experiences a loss of production time.

Both OEE and Six Big Losses have their roots in Total Productive Maintenance, and one of the most important goals of TPM is to reduce and ultimately eliminate the Six Big Losses. Eliminating the Six Big Losses would translate into a major improvement in manufacturing efficiency.

Similar to OEE, Six Big Losses also addressed three core elements: Availability, Performance, and Quality:

Availability losses

- Unplanned stops. Stops during Planned Production Time due to equipment failure or other unplanned reasons

- Planned stops. Stops due to planned setup, adjustment, or maintenance.

Performance losses

- Small stops. Minor stops (under 5 minutes) or required idle time during Planned Production Time.

- Slow cycles. Reduced speed during Production Time, for example, due to overheating.

Quality losses

- Production rejects. Defective parts or products produced during stable production time.

- Startup rejects. Defective parts/products that are produced between the startup and the stable (steady-state) production time.

Addressing Six Big Losses to improve manufacturing efficiency

Using OEE monitoring software and the Six Big Losses framework provides a clearer roadmap for businesses to improve their OEE score and, in turn, their manufacturing efficiency:

- Reducing availability losses. Working to reduce Unplanned and Planned Stops due to equipment failure or excessive setup, adjustment, and maintenance time so equipment can run 100% of the time during the Planned Production period.

- Reducing performance losses. Reducing and ultimately eliminating loss in production due to idling (Small Stops) and reduced production speed (Slow Cycles), preventing these minor stops and slowdowns from accumulating to hurt overall manufacturing efficiency.

- Reducing quality losses. Reducing process defects (Production Rejects) and reduced yield (Startup Rejects) will help the business reduce the number of defective and unusable products/parts during startup and the stable (steady-state) production time.

Below, we will have a more in-depth discussion on how businesses can address these losses to improve efficiency, starting with addressing quality losses.

Reducing availability losses

In the efforts to reduce and ultimately eliminate availability losses, there are two main focuses: reducing equipment failure and minimizing planned stops.

Minimising Planned Stops

Planned Stops, also often called Setup and Adjustments, refer to any significant period of time in which a piece of equipment cannot operate during a Planned Production Time due to tooling adjustments, changeovers, setups, cleaning, quality inspections, and other planned reasons.

Changeover, also called setup, startup, or warmup, is typically the largest source of planned stop time.

An important foundation for reducing Planned Stops is to establish a clear and consistent policy, especially in how you measure Setup Time.

There are two basic ways to measure Setup Time, but it can vary depending on the nuances surrounding your unique manufacturing process:

- The period between the last non-defective product produced before Setup and the first non-defective product after Setup, or

- The period between the last non-defective product produced before Setup and the first instance of consistently producing non-defective product after Setup (in this approach, startup or warmup time is considered a part of the Setup period.)

Both approaches are perfectly fine, and as mentioned, you can use your own unique measurement depending on your needs. What’s important is to document this policy, make it available to your stakeholders, and implement it consistently.

Implementing SMED (Single-Minute Exchange of Die)

Another popular and effective method for reducing Planned Stops is to establish SMED.

Simply put, SMED is a system for dramatically reducing the time it takes to complete a Setup to less than 10 minutes (single-digit minutes, hence the name.)

It involves thoroughly dissecting and analyzing the Setup process into smaller elements to assess whether each element can be:

- Streamlined. Modified to be faster

- Separated. Moving a process before or after the setup to shorten the actual Setup time

- Converted. Modified first so that the modified process can be moved before or after the Setup

For example:

- Preparing parts in advance (so the part preparation can be moved before the Setup period)

- Eliminate inefficient fastening method with a quick-release mechanism (streamlining the process)

- Modifying equipment so that it can perform two processes in parallel (converting internal elements into external)

Using reason codes to address Unplanned Stops

Reducing the occurrence of Unplanned Stops due to equipment failure can be quite challenging in practice since each failure may have unique causes with unique nuances.

Thus, an important prerequisite when addressing these Unplanned Stops is to first identify the root cause of the issue and understand the nature of each issue.

One of the best approaches to do so is to leverage the use of Reason Codes, or also called Failure Codes, for example ARLK for air leaks, CALB for calibration-related issues, ADJS for equipment that currently requires adjustments, and so on.

By attributing each instance of an Unplanned Stop to a reason code, we can accurately apply Root Cause Analysis (RCA) and identify top causes.

Here are a few tips on using Reason Codes:

- Every reason should describe symptoms rather than attempting to describe root causes

- It’s best to start small with no more than 20-30 reason codes to avoid overwhelming yourself.

- To avoid using too many codes, it’s best to create a catch-all code like “All Other Reasons,” “Other Causes,” or “Other Reasons” to cover reasons that aren’t too specific

- However, this catch-all reason shouldn’t be in your top ten causes. Add new reasons as needed to avoid such a situation.

- For reasons with unique codes, make sure each of them is clear and easily distinguishable from other reasons

Evaluate regularly, and remove codes that aren’t regularly used.

Reducing performance losses

The most important foundation in addressing and reducing performance loss is to accurately identify and understand your equipment’s Ideal Cycle Time.

The Ideal Cycle Time is the theoretical fastest cycle time that the manufacturing process can handle, assuming optimal circumstances.

It’s very important to measure your Ideal Cycle Time accurately, or else you may unknowingly mask loss production time, which can hurt your business’s productivity and effectiveness in general.

Once you’re sure that you’ve identified an accurate Ideal Cycle time, analyze your data and look for patterns of sudden performance losses. For example, if there’s an unusual number of Small Stops after any specific material change.

Apply Root Cause Analysis (RCA) or other analytics methods to identify the root cause of these losses so you can figure out the appropriate solutions.

In most cases, Performance loss scenarios can be addressed with the following solutions:

- Improving the condition of equipment through various means.

- Schedule preventative maintenance (i.e., lubrication, regular services) to reduce/eliminate downtime due to equipment failures.

- Establish material quality standards and tighten control.

- Train human resources on optimal and standardised manufacturing process procedures

- Configure the equipment to ensure precise and optimal operations

Reducing quality losses

As discussed above, quality losses come in two forms: Production Rejects and Startup Rejects.

Most tools and machines require a startup or warmup period in which they haven’t yet reached an optimal production capability, so they typically have reduced yield during this period.

With that being said:

- Production rejects are defective products/parts produced during stable production time (after the startup/warmup period has finished.

- Startup rejects are defective products/parts produced between the startup/warmup period and the stable production period.

One of the most effective methods to reduce quality losses is to reduce variation (ensuring all manufacturing processes are as consistent as possible), especially in equipment configuration/setting and materials used.

It’s advised to establish and implement more precise equipment settings, if possible, on a part-by-part basis. Also, try to run material tests on different equipment to ensure consistency.

Reducing variation may also be effective in reducing/eliminating performance losses. for example, optimal and consistent equipment configuration may help reduce equipment failure.

Implementing SIC

Another popular and effective method for addressing quality losses is to implement SIC (Short Interval Control.)

Simply put, SIC is a method for dividing production shifts into smaller intervals of time, typically 2-4 hours each. The idea is that the shorter the interval is, the easier it will be to identify bottlenecks/issues and implement tighter controls to maximize productivity.

To maximize SIC implementation, plant-floor employees should leverage data to identify, plan, and implement improvement actions.

When implemented correctly, SIC can be very effective not only in reducing quality losses but also for all types of losses by shortening the time in which countermeasures to problems can be proposed and implemented.

Additional actionable tips on improving manufacturing efficiency

- Establish a preventive maintenance program

All machines and tools, no matter how advanced and expensive, will always require maintenance so they can work at their most optimal levels. However, maintenance will also translate into downtime, which will contribute to lower ineffectiveness and inefficiencies in operations.

With that being said, finding the right balance between minimising downtime and performing maintenance before the equipment experiences failure can be very challenging in practice, and this is where establishing a comprehensive preventive maintenance program comes in.

The idea behind a preventive maintenance program is to schedule maintenance tasks based on the known schedule of wear (and failure) for a particular machine. This way, companies can perform maintenance on a specific tool before it’s necessary, but not so often that the maintenance causes too much downtime.

When planning a preventive maintenance program, companies can collect and analyse data regarding past failures, as well as consult the tool manufacturer on its known schedule of wear.

- Monitor, evaluate, and improve your current manufacturing workflow

A key aspect of improving manufacturing efficiency is identifying areas for improvement in your current manufacturing workflow.

To do so, we can monitor and review three critical areas in your workflow: equipment, human resources, and processes:

- Equipment: review all tools, machines, and technology solutions involved in the manufacturing process. Do these tools work optimally? Are there machines and tools that are currently contributing inefficiencies to the whole operation? How easy is it to implement changes in the manufacturing process?

- Human resources: even if all your equipment is in perfect condition, human errors can cause ineffectiveness, errors, and inefficiencies. Evaluate whether your current team members have the right skills to perform their responsibilities and closely monitor whether tasks are finished on time (and whether they can be performed faster.) Identify any bottlenecks caused by human errors and figure out the solutions.

- Processes: analyze current systems, policies, and processes to determine whether they are working as planned and identify where the bottlenecks are. Use this data to develop an improvement plan and compare the results of these optimizations to previous conditions.

Regularly monitor your workflow, and strive to continuously make data-driven improvements to your manufacturing workflow.

- Automate your data collection

One of the key ways to improve Overall Equipment Efficiency (OEE)—and thus, manufacturing efficiency—is by ensuring a real-time and accurate collection of production data.

Even the most advanced manual data collection or, even worse, paper-based data will always involve inaccuracies and delays, so the company will be disadvantaged and delayed when it comes to making real-time decisions and solving problems. This delay and inaccuracy in data collection alone can significantly contribute to the ineffectiveness and inefficiencies of the manufacturing process.

Fortunately, integrating automated real-time data collection is now much easier and more affordable. LineView offers a comprehensive smart factory solution to automatically perform OEE and True Causal Loss analysis on each of your production lines, providing you access to real-time data for improvement.

In practice, collecting equipment and operator data in real-time can provide an immediate improvement to productivity, especially by quickly identifying any tools and machines that are currently performing at a suboptimal state.

- Optimise your material usage

One of the biggest contributing factors to manufacturing inefficiencies is excessive material waste, and here are some actionable tips on how to reduce it:

- Optimise your design. The most ideal way to reduce material waste is to design your products to use fewer materials, for example, by adopting the value engineering design methodology.

- Optimise your workflow. Another important approach to minimizing material waste is to optimize your workflow to utilize all available materials as much as you can. Can any of your materials be reused instead of discarded? The fewer materials you discard, the more efficient your manufacturing process will be.

- Optimise your shipping. If you are not careful, the cost of shipping your materials can add up in the long run. Make sure to optimize the shipping process as much as you can.

- Recycle. The most efficient manufacturing process is one where you can effectively use your recycled material. However, even if you can’t use the recycled material yourself, you can always sell it to others, turning waste into a potential source of additional revenue.

- Invest in training your human resources

Even if you’ve optimized all other aspects of your manufacturing process, it will only be as efficient, productive, and effective as the weakest member of your team.

Don’t underestimate the importance of having strong human resources in improving your efficiency, and investing in real-world training remains the most effective method to improve your human resources.

The ideal scenario is when every team member has a clear grasp of their roles, their tasks, and how to execute the manufacturing workflow from start to finish as efficiently as possible, and regular training is the way to achieve this.

- Standardize everything

Different team members may have different approaches to executing tasks, but while they may have good intentions in doing so, how they do things may not be the most efficient.

Set clear and comprehensive policies to standardize every task from the simplest one to the most complex one so you can ensure efficiency.

Make sure to communicate your policies and checklists so that every employee on the shop floor can follow them. You’d be surprised how standardizing operations alone can be very effective in reducing downtime and improving performance while ensuring optimal product quality.

- Optimize your supply chain

Don’t underestimate the role of your suppliers in helping you achieve manufacturing efficiency. Monitor and analyze each supplier. If a supplier constantly delivers: competitive costs, consistently high-quality materials, and so on, make sure to build good relationships with them and, if necessary, reward them by giving them more of your business.

To maximise efficiency, it’s also important to work with suppliers and vendors with responsive, high-quality customer service so you’ll be able to troubleshoot any issues related to them faster while minimising potential losses.

- Implement cellular manufacturing methodology

Another effective approach to improving manufacturing efficiency is to adopt cellular manufacturing.

Simply put, cellular manufacturing is a methodology in which similar processes are grouped together while dividing workspaces into ‘cells.’ Each cell is assigned a standardised set of tasks, so the human resources and equipment in each cell can focus on this single task or similar group of tasks rather than carrying out a wide variety of tasks (which can often lead to inefficiencies and errors. )

With the cellular manufacturing methodology, you are also required to view the manufacturing process as a series of separate steps, so monitoring and improving each cell will be a lot easier. This approach can also significantly help when it comes to reducing waste.

Wrapping Up

While achieving 100% manufacturing efficiency can be very challenging, by following the tips and strategies we have shared above, you should be able to gradually improve your efficiency, little by little, without sacrificing productivity.

In general, you can improve efficiency by reducing/eliminating waste, improving equipment effectiveness and efficiency (by improving OEE), optimising material yield, and improving labor efficiency. By focusing on these areas, you should be able to notice improvements in your overall efficiency.

Since improving manufacturing efficiency is a long-term game, it’s important to continuously monitor your progress and collect production data in real-time so you can more quickly and accurately make decisions and solve problems as you go, minimising downtime to ensure efficiency.