I’ve spent a lot of time in manufacturing facilities around the globe. Some plants have robust digitalisation, with fully integrated end-to-end systems. Other plants barely have Wifi.

Why these disconnected plants still exist usually boils down to the traditionally high barrier to entry into digitalisation. It’s often true: typical MES platforms are expensive and can be tricky to integrate into existing facilities.

Dedicated OEE software, on the other hand, could come as a fully integrated line information system. When paired with the right routines, it becomes a powerful tool that can allow plant managers to instantly identify the highest impact opportunities for targeted productivity gains, and quick return on investment.

MES platforms versus OEE software: there’s certainly a lot of crossover between the two systems. It’s my firm belief that the factory of the future will rely on integrated, fully automated OEE software.

Let’s dive into each type of production solution and try to unravel each of their pros and cons for OEE improvement.

What is an MES Manufacturing Platform?

Most often defined as an integrated development environment, MES (Manufacturing Execution Systems) platforms give operation managers the tools to create various industrial applications, like SCADA (Supervisory Control and Data Acquisition).

Users can build out elements like HMI screens, and customise reports to meet their specific operational needs.

Flexibility within MES comes at a price, however, as systems need to be developed from the platform’s building blocks.

Initial and ongoing development responsibility is shouldered by in-house teams and contract integrators which is a drain on time and resources. Often, systems inevitably go stale after years of stagnation and lack of updates.

Core MES features

Data collection: MES systems should have the capability to collect data from along the manufacturing line and factory floor. Depending on the existing level of interoperability in your plant, the possible dataset can vary. The MES should be able to collect the data, store it, and make it available for data analysis.

Production scheduling: Production planning can be done directly in most MES platforms right down the hour. When integrated with your company’s ERP (Enterprise Resource Planning) software, data can be shared across business units.

Resource management: The MES software will streamline and digitise resource management. That could mean human resources like staffing and shift planning, or equipment planning and maintenance on machinery, entire production lines, and even things like forklifts and vehicles.

Performance analysis: The first step towards process optimisation is performance analysis. MES platforms have the capability to do analysis on production output levels, OEE data, and other key metrics like cycle time and total effective equipment performance.

MES trends and modules

On top of the core features of an MES, there are optional modules that can be used to tailor the platform to meet the specific needs of modern companies and manufacturers. The baseline option with the above core features can be bolstered by purchasing additional modules if your plant needs extra features.

These additional modules can include things like specific hardware integration, targeted plant-specific data tracking, or custom dashboards for better visibility and visualisation.

As technology evolves, and market demand shifts, MES developers also adapt with trends. Modifications to an existing MES to stay up to date with these trends are possible, but may come at a steep price.

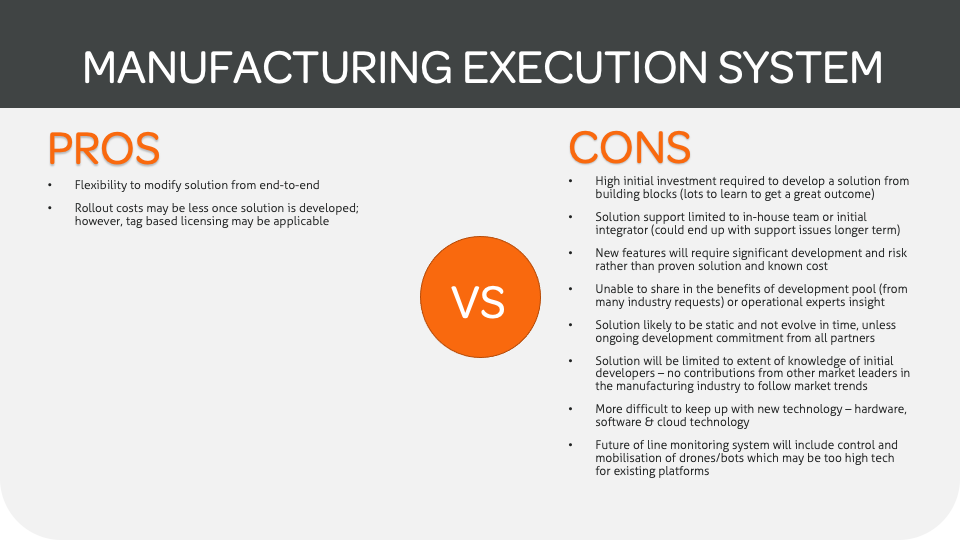

MES Pros vs. Cons

What is an OEE Software Solution?

Purpose-built Overall Equipment Effectiveness (OEE) solutions are designed with the sole purpose of improving operational and production efficiency, and are proven to deliver fast and sustainable performance improvements.

By purchasing an out-of-the-box OEE solution, in-house teams simply have to configure the software and are not tasked with development nor ongoing maintenance. In fact, the agile team at LineView maintains constant focus on the needs of operations teams. Plus, new features and related modules are introduced to the market on a regular basis to keep systems current. Meanwhile, simple drag and drop style user configuration does not require any programming skills. This low code/no code software enables customers to rapidly deploy a solution at lower cost.

We have also developed a proven way of working with the system to ensure results and have realised remarkable efficiency improvements. When these processes are deployed in conjunction with our LineView system, manufacturing operations benefit from greater efficiency, lower costs and complete manufacturing improvement.

Core Functions of the OEE Solution

An OEE software like LineView is - first and foremost - agile and flexible to meet the operational needs of your facility. We know that every shop floor is unique. That’s why we highly recommend OEE software to operations teams who want to be in control of every aspect of their line.

A great OEE software solution should have a mix of features that are tailored from the start. But one of the most powerful aspects of OEE software is the adaptability to add and modify features as needed.

- Browser-Based Interface: Access anywhere, anytime from desktop or mobile devices from an interface with role-based logins

- Real-time Feedback: Flag urgent problems like machine stoppages, product quality issues, or raw materials shortage for immediate corrective action

- True Causal Loss: Fully automated casual loss function, down to machine fault level, to get to the root cause of any issue, and track downtime without reliance on manual input

- SAP / 3rd party ERP System Integration: Create a hub for all operational data, independent of any OEM

- Drill-down Capability: Effectively analyse productivity loss by line, area, machine, fault, or parameter

- Configurable Maintenance KPIs (Key Performance Indicators): Real-time insight like Mean Time Between Failure/To Repair to have a view on the state of your machines and compare SKUs, teams, or shifts.

- Automated Data Capture: Interfaces with existing data sources for automated data capture direct from PLCs (Programmable Logic Controllers). This feeds into Artificial Intelligence (AI) and machine learning. for continuous improvement

- Line Balance Monitoring and V-curve Analysis: Intuitive visual representation to help optimise production line balancing, maximise availability, and minimise production losses.

- Clean-in-Place (CIP) monitoring for compliance, and improving the balance between effective CIP protocols and a faster cleaning time with lower chemicals use.

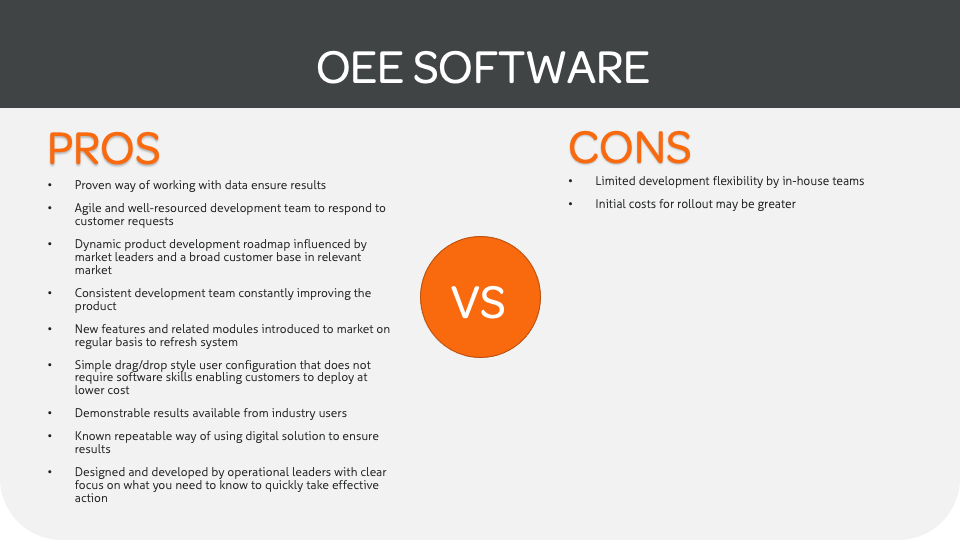

OEE Software Pros vs. Cons

More than OEE Score: The future of manufacturing insights

An OEE software solution is more than just an MES alternative. It goes beyond OEE.

Data correlation across manufacturing processes links machines and operators. Every action and every process is digitally recorded, analysed and shared with the cloud. Simply put, OEE software is the key to the factory of the future, and to Industry 4.0.

Sharing real-time production data, as well as storing historical data, allows a connected factory to use company-wide information holistically to make intelligent and data-driven production decisions.

What are the differences between running an MES versus OEE Software?

Difference 1: Performance Management vs Line Information

The first difference that we saw during our comparisons of various systems is that LineView helps holistic performance. Every area can be improved as it’s not just about the data - it’s the tools combined with people engagement and best manufacturing practices that will extract meaningful results from that data.

MES Platforms can be very good at showing the data that a specific client has requested, but there may not be a system or a method behind it to extract performance value.

Difference 2: Speciality vs Specificity

MES Platforms are useful if you know exactly what you want to ask it to do for you. They can be fully modular and can be displayed and written to output various metrics and KPIs. However, this specificity comes with a risk: you must know what you want to get it to do!

LineView knows what to look for, and presents key operational metrics in a way that zooms in on the problem to be solved.

Difference 3: Run up time

Most MES platforms integrated into manufacturing operations have very tailor made systems that will take longer to get going. On the other hand, LineView has a much faster ramp up time from order to delivery as they know how to get the system to work and deliver improvement quickly.

Difference 4: Interfacing into other systems

Many MES solutions allow for lots of custom builds and modules to be written to make it fully workable. For example, the additional metrics of water and energy monitoring could be a great advantage for certain industries and plant types.

However, the strength of Lineview is that it can interface through MS Azure in a more powerful way, rather than having to bolt on other modules and only use a legacy system that is forced to interface. The system could ingest data through LV connectors as well as interfacing through MS Azure tech stack with other data repositories.

ROI for the Win: Your Plant Deserves an OEE System

The Factory of the Future will be agile. Flexible enough to meet rapidly evolving market demands, but also built upon a foundation that can integrate new, innovative technology.

The only way to prepare for this smart, connected factory is to equip your plant floor with an OEE system.

There’s no question that MES Platforms have, by and large, left a positive mark on manufacturing operations worldwide. But just because a system works, doesn’t mean we can’t strive for better, or faster results.

OEE Software, like LineView, offers the performance benefits of an MES but with a modern and future-proofed web of features, modules, and potential for growth. Real-time information is shared across the shop floor, offering unprecedented transparency and connected functionality.

At LineView, our best-in-class system has been built out over twenty years, refined with the input and combined experience of blue chip packaging customers. Industry-specific insight, trends, and production processes are fully integrated into our robust OEE improvement solution that is fast to deploy and offers demonstrable results from industry leaders around the globe.